- Stock: Out Of Stock

- Model: TBK-988Z

- Weight: 3.50kg

TBK-988Z LCD Screen Separator Vacuum Screen Separator Machine with 360 Degree Rotatable Heating Plate

Features:

- Built-in double large vacuum pump

- New upgrade super suction

- 360 degree rotation of heating platform

- Front and back easily removable movable fixture

- For curved screen with frame glue removal and separation

- Easy to use and easy to operate

- It can work as vacuum LCD separator for mobile phone with curve screen's size is 7 inch or below.

- Most convenient, very cost-effective

- Small size and light weight

- Designed for small repair shop

Specifications:

- Product Model: TBK-988Z

- Working Voltage: 220V/110V

- Product Power: 250W

- Product Size: 24*13.5*15cm

- Working Area: 8*18.8cm

- Heating Method: constant temperature heating

- Net Weight: 2.6kg

Package Included:

- 1 x Set of Screen Separator Machine

Note: Other tools and items pictured are not included.

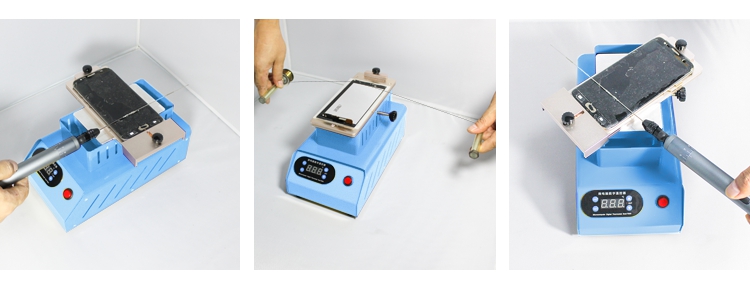

Operation Steps:

1. Turn on power supply: Insert power cord into the power connector on the rear of the separator and turn on the power switch.

2. Preset temperature: press SET key to preset temperature, press up key to set the temperature to about 85℃, press ENT to save.

3. Prepare wire handle: Equipped with wire handle to separate screen.

4. Place silicone anti-skid pad: place it on the panel of the separator, align the rubber pad with the hole of the panel.

5. Screen separation preparation: Put screen to be separated into the center of the panel, press Start key to start vacuum suction, and ensure that the screen is sucked.

6. Start cutting the screen: the screen can be cut after warming up for 3-5 minutes.

7. After separating the broken screen, turn off the power supply of the separator. If it is dry glue, you can directly tear it off by hand. If it is water glue, it needs to be removed with the help of blade and glue removing liquid.